MANUFACTURING

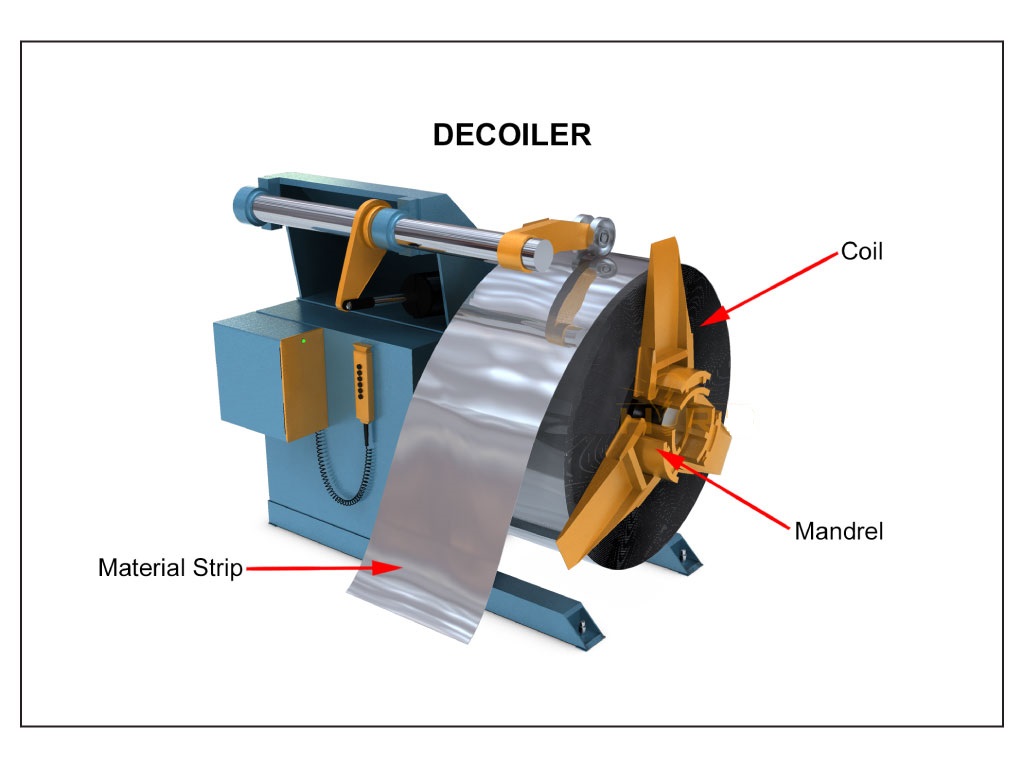

1. Uncoiler

The roll forming process begins with the loading of the coil onto the decoiler.

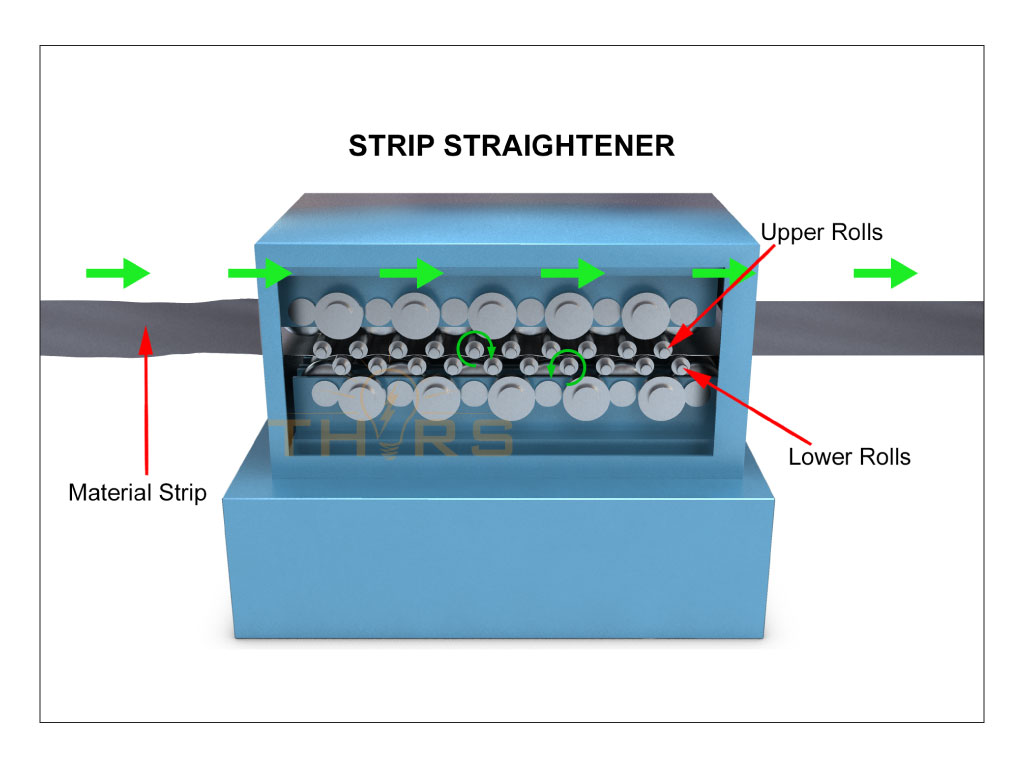

2. Straightening

The coil rotates to unwind the material strip into the strip straightener.

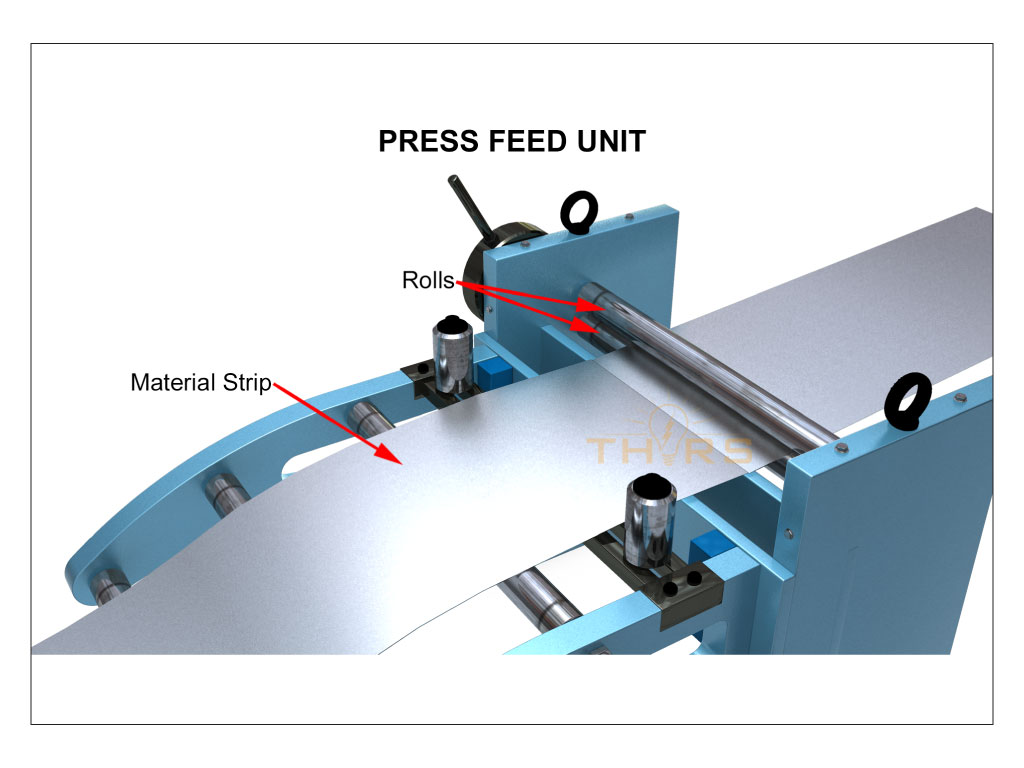

3. Press Feed

The strip straightener levels the material strip to remove pre-existing defects before the strip enters the press feed unit.

4. Punching (If)

The press feed unit feeds and guides the strip to ensure a smooth entry into the pre-punch press. In the absence of the pre-punch press, the press feed unit directly feeds the material strip into the roll forming machine.

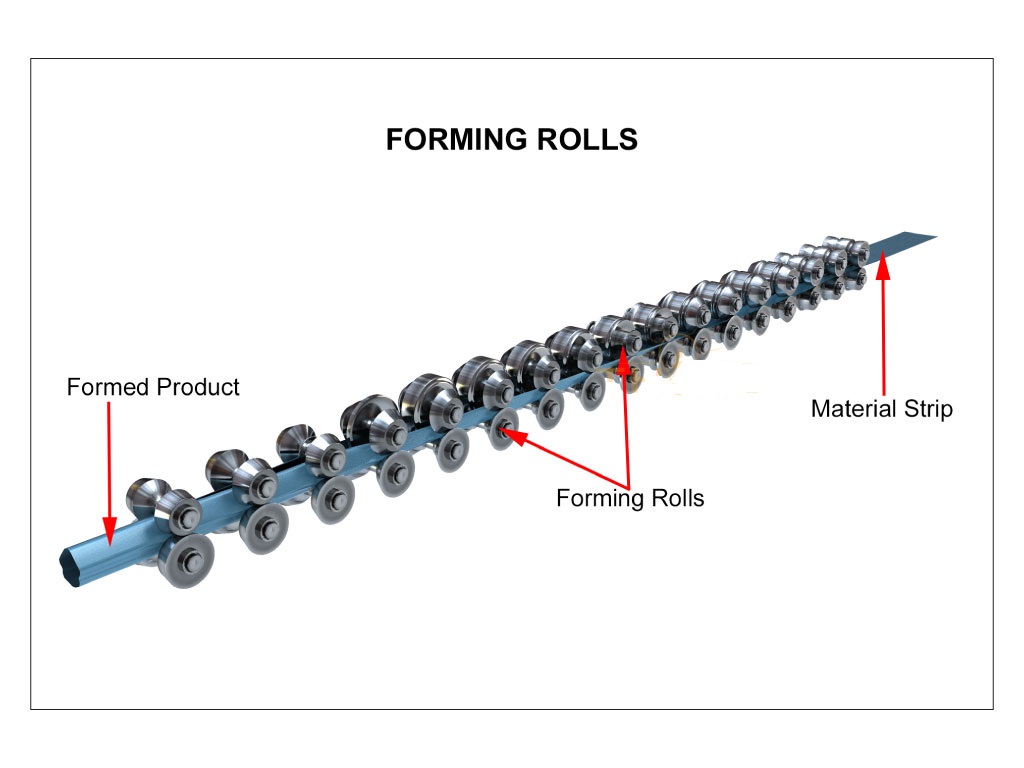

5. Forming Roll

The roll forming machine uses a series of forming rolls that shape the material strip. Each pair of forming rolls gradually imparts the shape to the material strip.

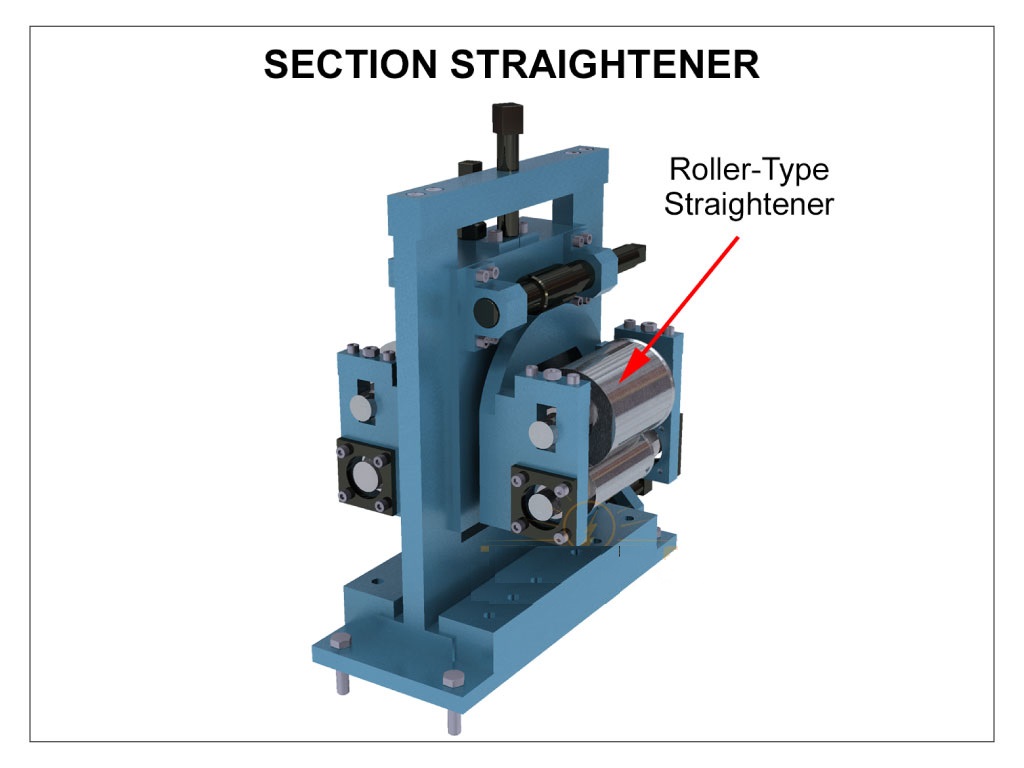

6. Section Straightened

Once the shape is fully formed, the product enters the profile straightener to remove any bends produced during the forming operation.

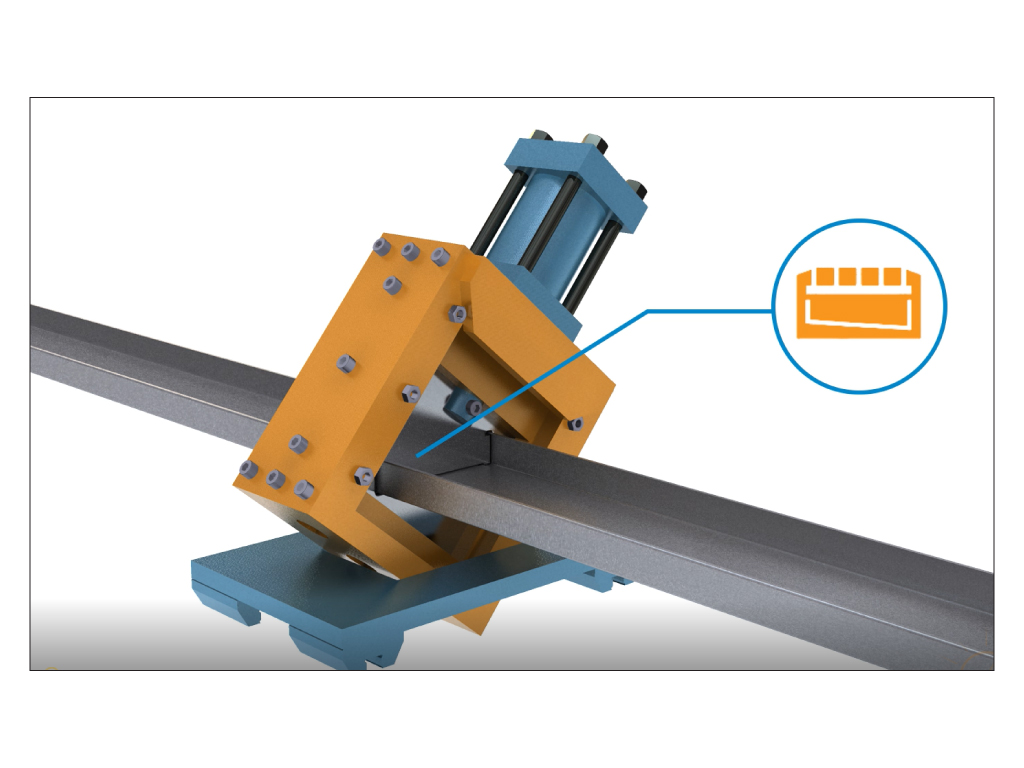

7. Cut-Off

The formed product then enters the cut-off press, is cut to the desired length, and is stacked on a run-out table along with the other formed products from the roll forming line. This is the last stage of the roll forming process.